Belief in superior quality in products and services prove to be paramount in excellent companies. Asian Refractories has spacious plant premises supported by the advanced state-of-the-art equipment and facilities. As firm followers of Good Manufacturing Practices (GMP), the company takes essential measures to improve technology for retaining environment safety as well as enhanced quality output. In 1993, we changed from a Coal Firing down Draft Kiln into an Oil Fired Continuous Tunnel Kiln, thus adopting a contemporary fuel saving technology. The current capacity of the unit is 2000 TPM of Shaped Refractory Bricks and 500 TPM of Unshaped Refractories (Monolithics).

Asian Refractories ensures smooth operations and productivity by maintaining adequate raw material inventory from the most reliable and established suppliers. Our sourcing of inputs ensures stable and cost-effective supply. The process layout is scientifically derived and affords a contamination-free environment. A high-tech in-house workshop enables regular machine maintenance, as well as development of spare parts and patterns.

Working in accordance with the operations, the Quality Assurance Department is diligently involved in the entire process of a thorough check of the incoming raw material to the in-process checks to the final testing and inspection. All procedures like grinding, mixing, blending and firing of the kiln temperature are closely monitored and studied. Customers are delivered the finished goods after their rigid scrutiny, ensuring zero defect output.

Asian Refractories prides the innovativeness it brings in new products and process developments. Our R & D Cell managed by highly qualified, experienced and dedicated personnel, works intensively round-the-clock to give proficient indigenous products and technology that have the potential to bring the emergence of new markets, operational benchmarks and immense product possibilities.

This further helps us to offer customized application-oriented solution in blending, mixing and firing, to arrive at a suitable prototype for mass replication. With such expertise and technical know-how, our team gives Asian Refractories the leading edge in research-and development, with most advanced and superior high-tech equipment. After all, the only way to achieve innovation is through tolerance of reasonable experiments, trials and errors and the risk of making mistakes.

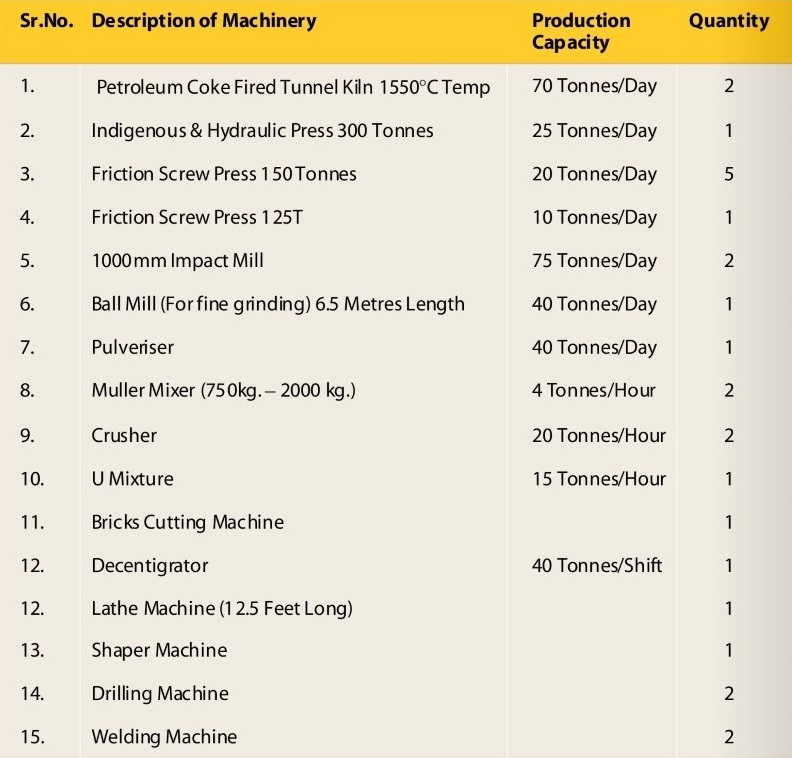

Belief in superior quality in products and services prove to be paramount in excellent companies. The company has spacious plant premises supported by the advanced state-of-the-art equipment and facilities.

As firm followers of Good Manufacturing Practices (GMP), the company takes essential measures to improve technology for retaining environment safety as well as enhanced quality output. In 1993, the company changed from a Coal Firing down Draft Kiln into an Oil Fired Continuous Tunnel Kiln, thus adopting a contemporary fuel saving technology. The current capacity of the unit is 2000TPM of Shaped Refractory Bricks and 500TPM of Unshaped Refractories (Monolithics).

The company ensures smooth operations and productivity by maintaining adequate raw material inventory from the most reliable and established suppliers. Our sourcing of inputs ensures stable and cost-effective supply. The process layout is scientifically derived and affords a contamination-free environment. A high-tech in-house workshop enables regular machine maintenance, as well as development of spare parts and patterns.

Belief in superior quality in products and services prove to be paramount in excellent companies. The company has spacious plant premises supported by the advanced state-of-the-art equipment and facilities. As firm followers of Good Manufacturing Practices (GMP), the company takes essential measures to improve technology for retaining environment safety as well as enhanced quality output.

In 1993, the company changed from a Coal Firing Down Draft Kiln into an Oil Fired Continuous Tunnel Kiln, thus adopting a contemporary fuel saving technology. The current capacity of the unit is 2000TPM of Shaped Refractory Bricks and 500TPM of Unshaped Refractories (Monolithics). The company ensures smooth operations and productivity by maintaining adequate raw material inventory from the most reliable and established suppliers. Our sourcing of inputs ensures stable and cost-effective supply. The process layout is scientifically derived and affords a contamination-free environment. A high-tech in-house workshop enables regular machine maintenance,as well as development of spare parts and patterns.